To Push or to Pull, That Is the Question?

Push and pull usually come as the opposite side, but in the case of telecommunication field, they definitely come hand in hand. Push-Pull or Pull-Pull cables are used for greater freedom in routing allowing for smaller bend radii in some installations. Their typical applications include vent air controls and mechanical starters in aircraft. This article today will address these two cables in detail.

Mechanical Control Cables

The basic design of mechanical control cables features a moveable core, either a solid-wire or a wire-rope cable that's free to travel axially inside an outer casing or conduit. Actuation of a lever at one end of the cable assembly will produce an output force and motion at the other end. The mechanical cable is designed under two criteria, Push-Pull or Pull-Pull cables. Mechanical control cables are widely utilized in furniture, vehicles, lawn mowers, and medical devices, as well as seats in cars and planes, which have a great impact on our every day life.

Push-Pull Cables and Pull-Pull Cables Overview

Push-Pull cables are called because of the use of actuation force in both the push and the pull modes. Solid core inners or solid core cables (stiffer cable) would best suit this application however the bend radius would be larger. Push-Pull cables have a greater capacity in the tension (Pull) mode than in the compression (Push) mode. Reducing the push load minimizes a core's tendency to displace the conduit and, reduces the potential for the unsupported core outside the conduit to kink, bend, or distort. The following image shows a LCUPC-HD Duplex Singlemode Pull Tab Fiber Patch Cable.

While Pull-Pull cables in most cases are more flexible and are used in the tension (Pull) mode. The design has an integral return spring maintaining the load on the cable returning it to the standby position. This spring allows the use of flexible cables allowing tighter radius. Maximum working loads should be minimum breaking load of the core plus a built in safety factor.

The Operation of Mechanical Control Cables

The function of the mechanical control cables being controlled and the routing of the cable need to be analysed. All the external variables such as load, friction, routing, stretch, length, bends, temperature, environment and contaminants, need to be addressed. Every one of the aforementioned could affect the operation of the cable. As noted above, mechanical control cable is composed of three main components, that is filaments, strands and the core. The filaments are wound together into strands, and in turn these strands are wrapped around the core, making a stable and efficient rope. These systems work by compression moving the cable in one direction while tension is able to pull it in the opposite direction. In this way the mechanical motion is possible.

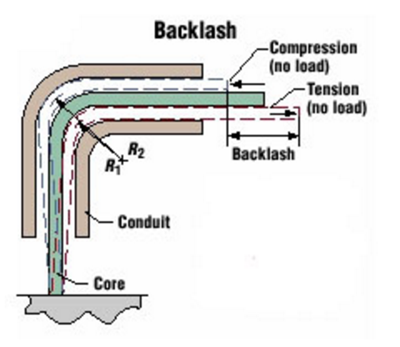

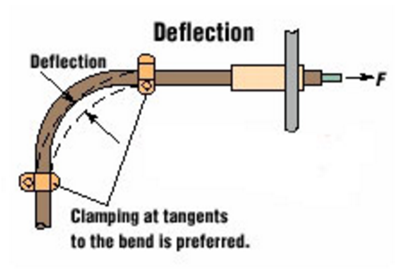

For example, Push pull cable assemblies are used to provide the mechanical motion in various systems performing a dual function that are subject to “lost Motion” between the input and the output ends when operating the cable. This loss is caused from a combination of backlash and deflection. This tolerance is evident in every cable made. Backlash is directly proportional to the total degrees of the bends in the installed cable, the clearance between the outer diameter of the core cable and the internal diameter of the conduit or casing. This will reduce the lost motion and any bending or damage to the exposed cable. The issue with many assemblies is that they are what is referred to as pull pull assemblies, and are only able to go in one direction, while these models offer multidirectional motion.

Summary

Mechanical control cables provide a simple, lightweight, economical, and reliable way to actuate throttles, latches and a thousand other mechanisms. Push-Pull cables would be recommended for light and medium duty applications with a maximum travel (recommended) of 200mm. While Pull-Pull control cables permit the use of most standard fittings allowing for a very wide range of mounting and retaining options. Fiberstore supplies a variety of push-pull cables terminated with LC or MPO connectors like Push-Pull LC patch cable and Push-Pull MPO patch cord. For more detailed information, please send your inquiry to us.

Reference:

http://www.drallim.com/drallim-share/pdf/DCB0010_Cable_brochure.pdf?pdf=DCB0010_Cable_brochure.pdf